October is National Pedestrian Safety month, and we know that pedestrians involved in motor vehicle accidents can not only suffer serious injuries but also incur significant medical expenses and lost wages resulting from those injuries. Recently, pedestrian death rates are the highest they have been in 40 years. In 2021, pedestrian death rates increased from […]

Category Archives: Safety

Keeping its passengers and employees safe while riding the trains is one of the main responsibilities of the Massachusetts Bay Transportation Association (“MBTA”), and when it fails to take proper safety measures, the public’s risk of injury increases. Back in April, we reported on a man dragged to his death when a Red Line […]

June is National Safety month, and one topic that is highlighted throughout the month is safety within the workplace. Job-site safety falls under the jurisdiction of OSHA, the Occupational Safety and Health Administration. OSHA’s responsibility is to ensure safe and healthful working conditions for workers by setting and enforcing standards that must be followed and by also […]

The Massachusetts Bay Transportation Authority (MBTA) is a semi-public entity, but that does not mean it is relieved from being held accountable when injuries to the public occur. Early morning on April 10, 2022, a 39-year-old Dorchester man, Robinson Lalin, died at Broadway Station when his arm got stuck in the door of an MBTA […]

Hard lessons can be learned from accidents. In the Tour de France a woman who held a cardboard sigh out during the race causing many racers to be injured was going to charged with a lawsuit, but was later released as a reminder of the importance of following safety rules.

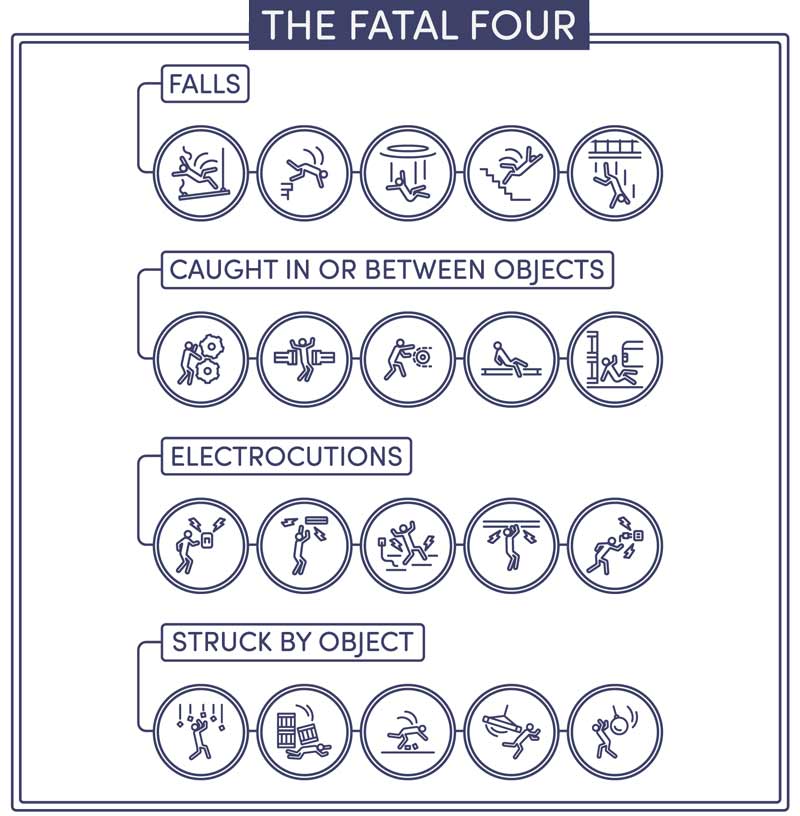

The four most frequent causes of death on construction sites have been labeled by OSHA as the “Fatal Four.” There were 5,333 deaths in 2019 alone that occurred as a result of fatal occupational injuries. The causes for death are listed here in order with the most first – Falls, Being struck by an object, Being electrocuted, Getting caught in between equipment and machines. Be sure to follow OSHA’s guidelines.

The control of hazardous energy as pertaining to lockout-tagout had over 2,000 violations in 2020. The purpose of controlling hazardous energy in this manner is to reduce/erase the potential harm to employees during the servicing and maintenance of machines and equipment in which the unexpected energization or start up of the machines or equipment, or the release of stored energy.

Ladders had over 2,000 violations cited in 2020. The regulations placed on the use of ladders on work sites is to diminish the risk of an employee becoming injured. OSHA has many specific rules for different ladders and work areas in the construction field. Some rules are how much weight a ladder can bear, using ladders together for extra height, and ladder care and maintenance.

Scaffolding requirements had over 2,500 violations cited in 2020. A scaffold should be capable of supporting its own weight and at least four times the maximum intended load to be applied to the scaffold. It may be necessary to consult an engineer to determine heavy-load points to prevent injury from occurring. Two main type of injuries that can occur from scaffolding violations are falling and either landing feet or head first. An employer at a construction site should

include a review of the scaffolding system,censure that workers have appropriate safety equipment, and place supervisors in charge that have the skill, experience, and training to ensure safe installation and dismantling according to the scaffolding manufacturer’s specifications.

OSHA established standards to protect workers against respiratory conditions resulting from contaminated jobsites. Respiratory Protection had over 2,500 cited violations in 2020. The purpose of this standard is to prevent atmospheric contamination of the workplace and to reduce the chance of breathing in air contaminated with harmful dusts, fogs, fumes, mists, gasses, smokes, sprays, or vapors.